Información Básica.

No. de Modelo.

Carbide hardfacing

condición

nuevo

certificación

iso9001

personalizado

no personalizado

garantía

6 meses

servicio posventa

6 meses

material

carburo de tungsteno

Paquete de Transporte

as Customer Demand

Especificación

FAE Seppi AHWI FECON SEPPEI

Marca Comercial

HONGZUAN

Origen

Hunan, China

Código del HS

8209101900

Capacidad de Producción

20 Ton Per Month

Descripción de Producto

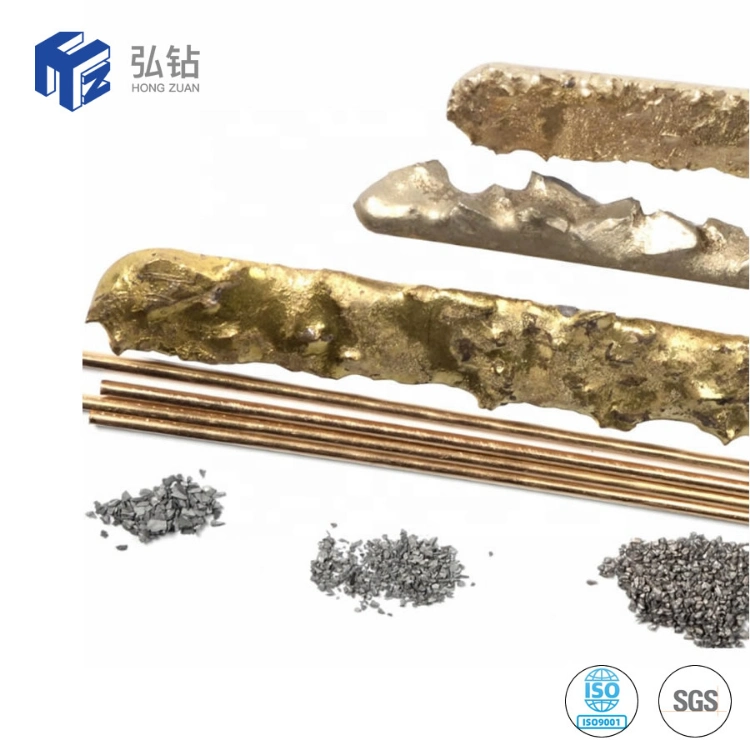

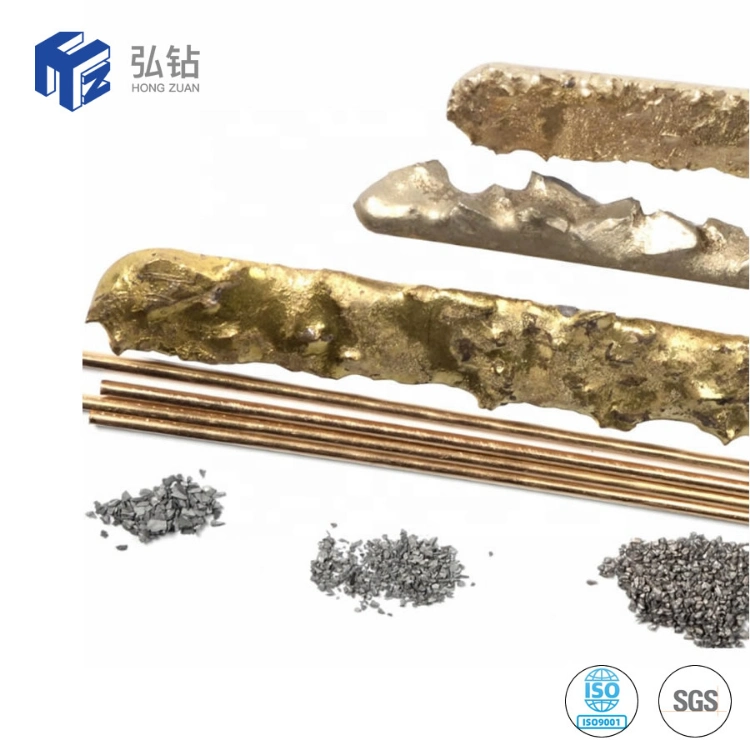

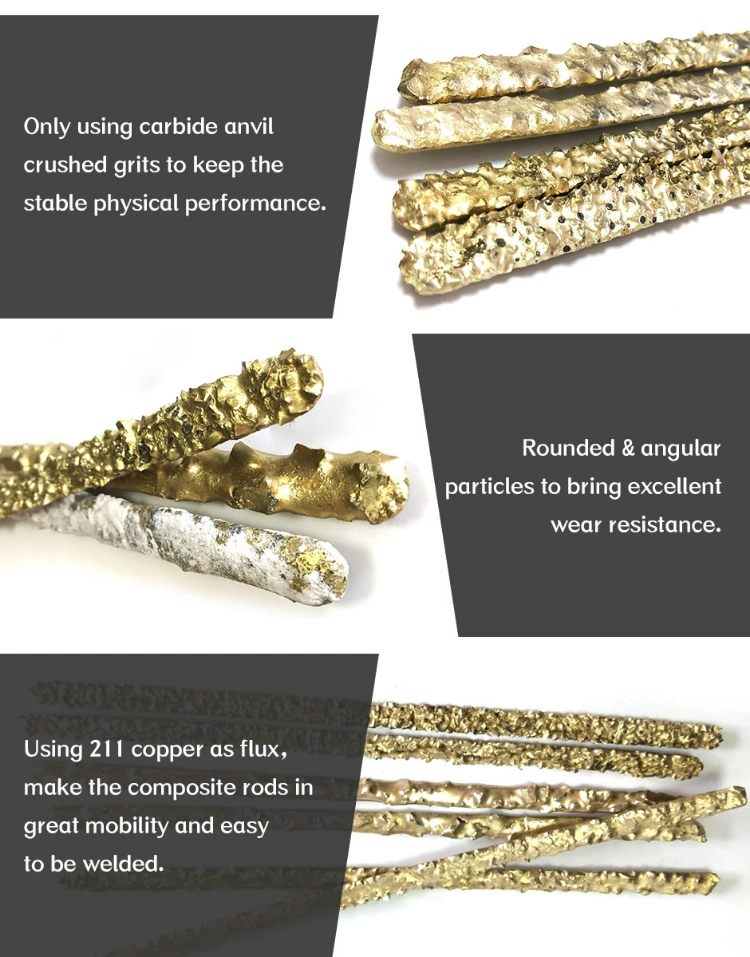

Feature of Tungsten Carbide Composite Rods

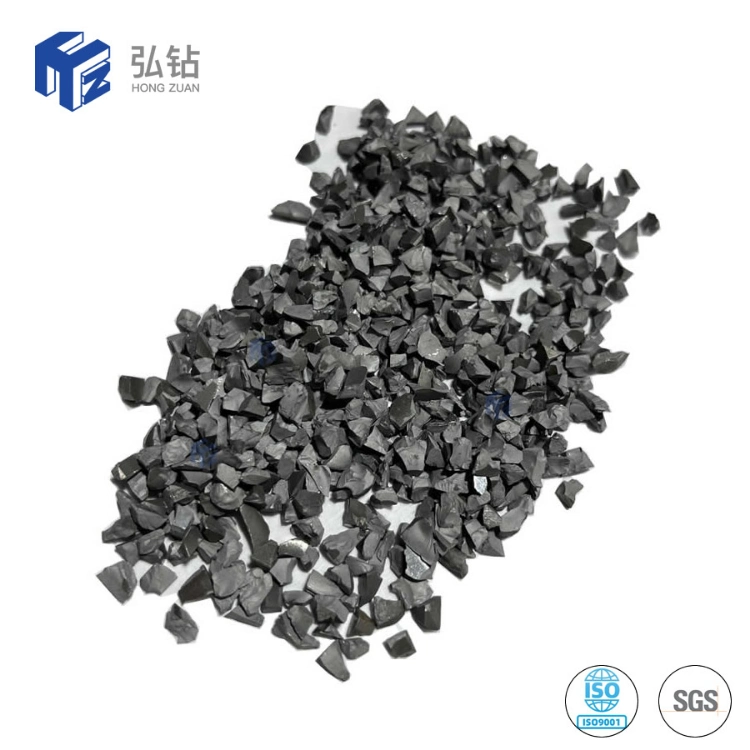

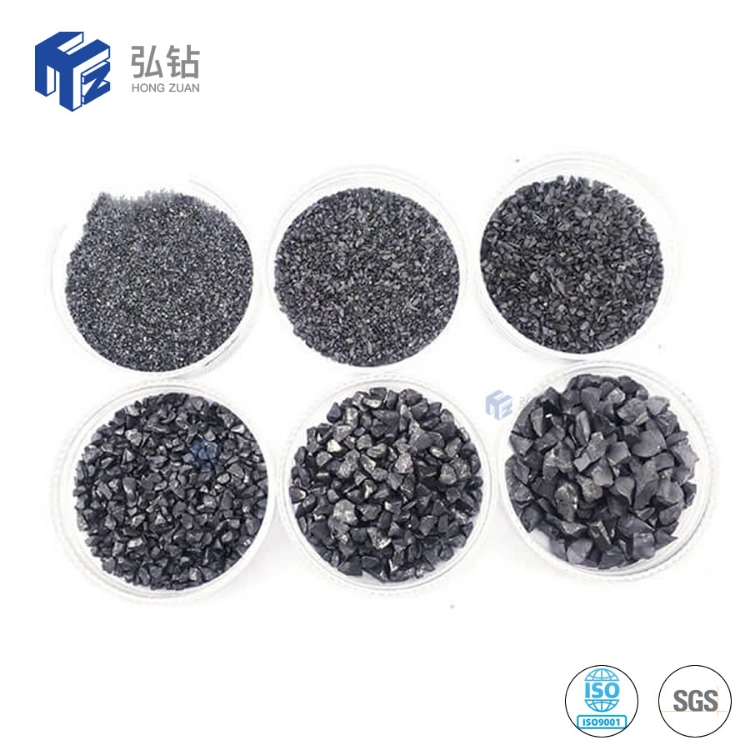

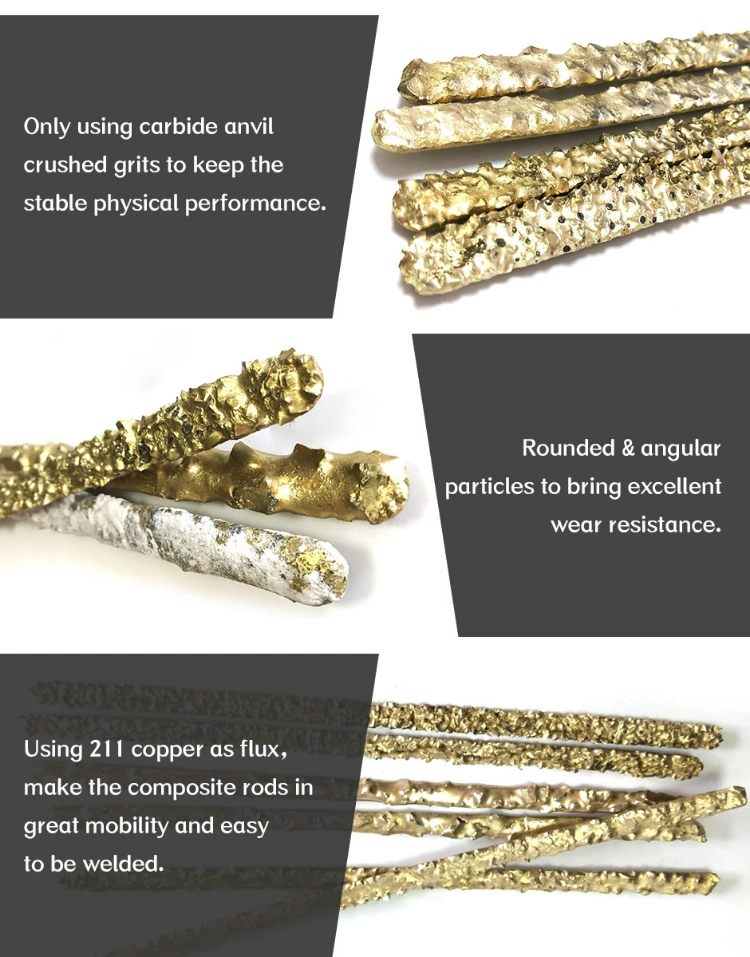

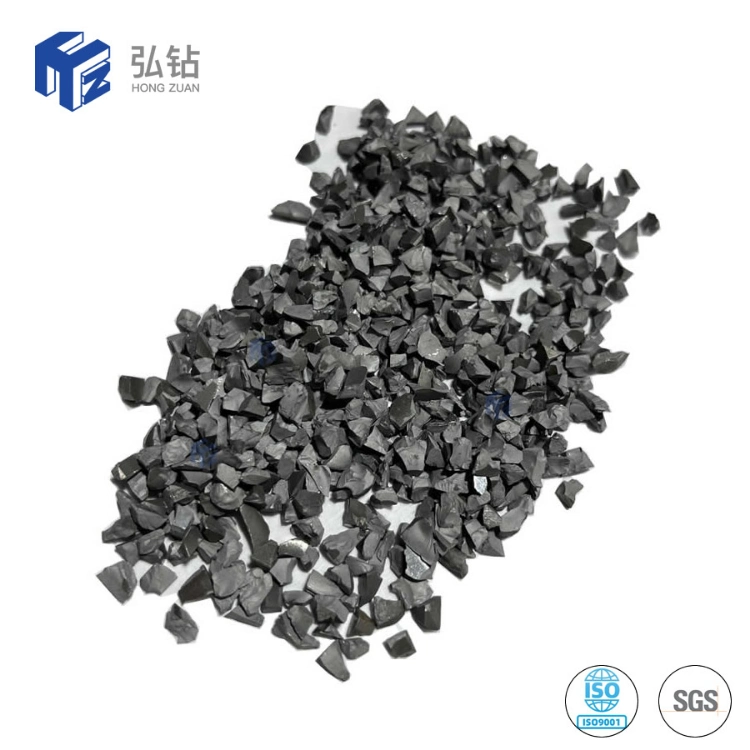

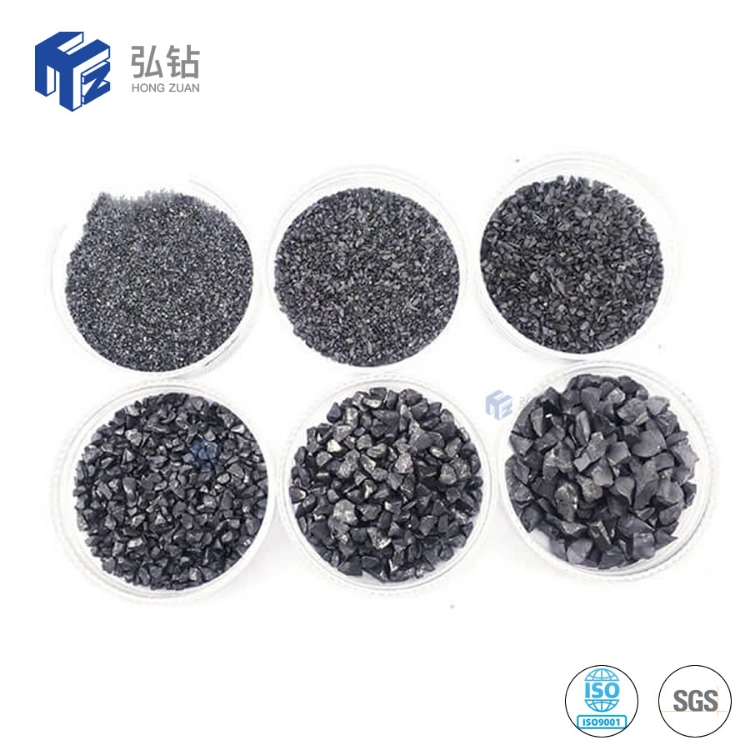

Specially selected Tungchip Tungsten Carbide Grit either "blocky" with sharp edges for cutting application or "rounded" Tungchip Tungsten Carbide Grit for wear applications are produced under stringent quality controls. Material is thoroughly cleaned to ensure the best possible wetting properties, both during manufacture and application. Stringent quality control procedures ensure repeatability of excellent quality, low fuming rod. The Tungchip Tungsten Carbide Grit is blended with a Copper, Nickel and Zinc alloy, to produce a premium quality Composite Rod.SIZES STOCKED

1/16" x 1/8" (1.6 x 3.2 mm)

3/16" x 1/8" (3.2 x 4.8 mm)

1/4" x 3/16" (4.8 x 6.4 mm)

5/16" x 1/4" (6.4 x 7.9mm)

3/8" x 5/16" (7.9 x 9.5 mm)

1/2" x 3/8" (9.5 x 12.7 mm)

Other sizes on request

SPECIFICATIONS

Standard Tungchip Tungsten Carbide Grit content = 65% Also available 50%, 60% & 70% Balance: Matrix (RbCuZn-D)

You can choose two items as follows,

A: tungsten carbide + copper(Cu) a little yellow color

B: tungsten carbide + nickel (Ni) a light white color

ROD WEIGHTS

AVAILABLE 225g, 450g (standard) and 650g Rod length 450mm

Application of Tungsten Carbide Composite rods

it is mainly used for surfacing welding the oil, mining, coal mining, geology, construction and other industries in some serious wear and tear or artifacts of both cutting. Such as: milling shoes, grinding, centralizer, reamer, drill pipe joints, hydraulic cutter, scraper, plough planer knives, core bit, piling drill, twist drill, etc.

Grade of Tungsten Carbide

| Grade | ISO | Density(g/cm3) | Hardness(HRA) | T.R.S.(N/mm2) | Application |

| YT5 | P30 | 12.9 | 90.5 | 2200 | Best strength, high impact and shock resistance among W-Co-Ti alloys, but comparatively lower wear resistance. Suitable for rough turning, rough planning, and semi-finish planning of carbon steel, and alloy steel including forgings, stamped parts, and cast iron surfaces during intermittent cutting. |

| YW1 | M10 | 13 | 92.5 | 1710 | Better hardness, resistant to impact load. A good grade for general purposes. Suitable for machining of ordinary steel, cast irons as well as steels hard to be machined such as refractory steel, high manganese steel, and stainless steel, etc |

| YW2 | M20 | 12.9 | 91 | 1880 | Higher wear resistance and strength, resistant to high impact load. Suitable for roughing and semi-finishing of ordinary steel, and cast irons as well as refractory steel, high manganese steel, and high-grade alloy steel, etc |

| YG6X | K10 | 14.8 | 91.5 | 1890 | Fine grain WC alloy, wear resistance higher than YG6, strength close to YG6. Suitable for machining chilled alloy cast irons, and refractory alloy steel, as well as finishing of ordinary cast irons |

| YG6 | K20 | 14.8 | 89.5 | 2050 | High wear resistance, better impact and shock resistance. Suitable for semi-finishing, and finishing of cast irons, non-ferrous metal, alloys, and non-metallic materials at moderate cutting speed |

| YG8 | K30 | 14.6 | 89 | 2520 | High strength, better impact and shock resistance, but lower wear resistance and cutting speed. Suitable for roughing of cast irons, non-ferrous metal, alloys, and non-metallic materials at low speed. |

| YG11C | 14.4 | 86.5 | 2450 | Chiefly for the inserts and buttons of heavy rock drill bits and rotary-percussive bits, coal-cutting bits and tricone bits to cut medium-hard and hard formations. | |

| YG15 | 14 | 86 | 2500 | It is stronger, and is mainly used as the inserts and buttons of rotary-percussive bits, heavy rock drill bits to cut hard and very hard formations. | |

| YG20 | 13.5 | 85 | 2600 | Mainly for the stamping dies used in the conditions of heavy impact load and large stress |

Company Profile

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located in the hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized in industrial, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications. Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc .

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located in the hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized in industrial, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications. Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc .

We have a professional QC team follow to the System of ISO9001:2015, Covering the Raw Materials Incoming, Production Processes,Finished Products and Packaging to ensure high quality products output.

We mainly produce Tungsten Carbide Ball and Seat, Agriculture wear parts plates, Carbide tips, Carbide tiles,

HPGR Stud pins, Brazed Inserts, Gripper Pads, Buttons, VSI Bars, Rod, Strips, PDC substrate, Weld on teeth,

Bushings, Wire Drawing Dies, Heading Dies, Seal Ring, Nozzles, and other customized carbide products.

Product packaging

FAQ

Q1 : Are you Factory or trading company ?We are Factory with 20 years of production experience.

Q2: What is the producing process?

Production process including raw material cutting, machine processing, grinding, accessories cleaning, assemble, cleaning,

stoving, oil coating, cover pressing, testing, package.

Q3: How to control the products quality?

All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Q4: What is the transportation?

If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.

Q5: Can you provide OEM service?

Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our products

Q6: How to place an order for Good performance nonstandard products by stellite alloy? 1. Fill your Order List in our online

Inquiry System (Also you can directly contact our salesperson by E-mail / Skype / Whats App) 2. We will make a feedback to you ASAP after receive your order list.

Q7: What's your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Q8:How to contact us?

You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on

Q4: What is the transportation?

If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.

Q5: Can you provide OEM service?

Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our products

Q6: How to place an order for Good performance nonstandard products by stellite alloy? 1. Fill your Order List in our online

Inquiry System (Also you can directly contact our salesperson by E-mail / Skype / Whats App) 2. We will make a feedback to you ASAP after receive your order list.

Q7: What's your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Q8:How to contact us?

You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on